A Mill 19-headquartered nonprofit is dispersing millions of dollars to projects working on collaborative robotics projects.

In January, the Advanced Robotics for Manufacturing Institute, aka ARM Institute, announced a call for technology projects to address areas of need in the US manufacturing sector. The call was open to members of the Pittsburgh-based org’s nationwide network of academic, technology and government organizations.

In collaboration with government partners, ARM Institute members could submit proposals to address topics in five areas: automated robotic task planning; multi-robot, multi-human collaboration, task sharing and task allocation; safe and scalable manufacturing of energetics; AI in robotics for manufacturing; and discovery workshops and market studies.

Last week, the ARM Institute selected eight projects for which it plans to distribute $1.56 million; because the projects are government funded, the teams will share costs, bringing the total contribution to $3.26 million across the projects, ARM Institute Senior Outreach Manager Livia Rice told Technical.ly. These projects were chosen because the ARM Institute’s leadership felt they were the most able to address the most pressing needs in the manufacturing sector at the moment, and allow the ARM Institute the chance to showcase its strengths.

“These projects epitomize the strength of ARM Institute members and the impact of collaboration between different stakeholders in manufacturing,” ARM Institute CTO Chuck Brandt said in the announcement.

Here are the projects that got funding:

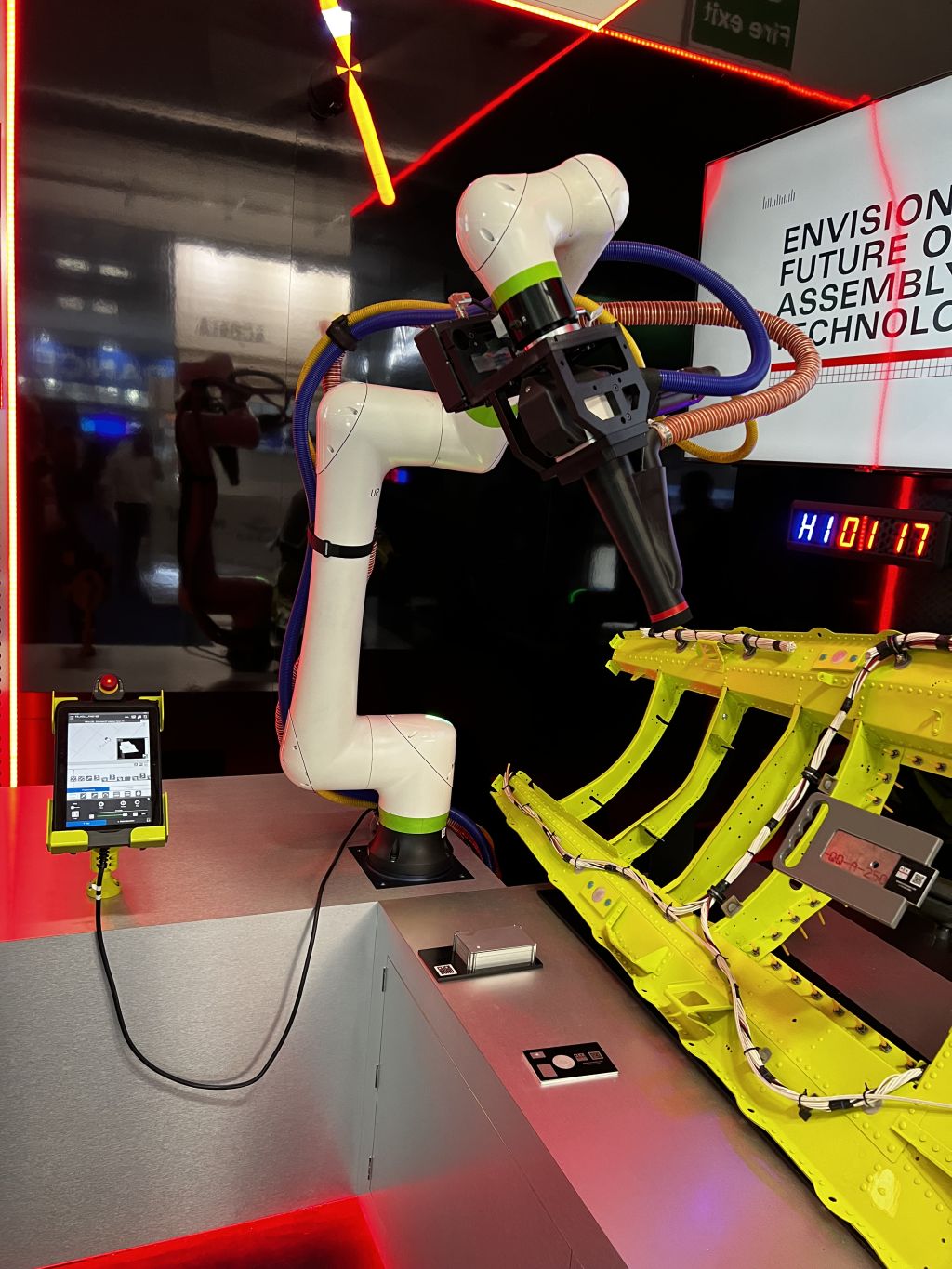

- Technology Assessment of Virtual Commissioning for Day One Manufacturing Readiness — This project comes from a collaboration between Wichita State University’s National Institute for Aviation Research, Siemens Corporation and Spirit AeroSystems, which will work together to develop a report that lays out the framework for creating virtual twins for digital testing.

- Autonomous Robotic Iterative Forging Phase 2 — This project comes from a partnership between Ohio State University, CapSen Robotics, Yaskawa, and Warner Robins Air Force Base and seeks to address the need for small-volume, high mix-manufacturing, in cases where manufacturers need to produce personalized medical implants.

- The Path to Adopt Multi-Modal AI and Rapid Re-tasking & Robot Agility Project — This project is a collaboration between Siemens and the University of Southern California and will build market studies and complete discovery workshops in order to provide assessments and propose technology roadmaps for multi-modal inputs for AI, rapid retasking and robot agility.

- Robotic Manipulation of Granular and Paste-like Materials — This project is seeking to use robotics to automate granular and paste-like materials to add to human operators’ ability to complete tasks such as scooping and pouring materials. The project will be executed through a collaboration between Siemens and the University of Southern California.

- Discovery Workshops/Market Analysis for Space and Hypersonics — This project has ASTM International as its principal investigator and will complete discovery workshops and market tudies centered on terrestrial manufacturing for space and manufacturing of hypersonic components and structures.

- Time-Optimal Motional Planning using Convex Sets — This project is a collaboration between Dexai Robotics and the Massachusetts Institute of Technology and has the goal of creating robots that can fill in the gaps left by the pandemic workforce shortages in restaurants.

- Manipulating Fabric with Robots for Pick-and-Place Operations — This project is a collaboration between the Apparel Robotics Corporation and MassRobotics and will develop robotic material handling capabilities in the clothing industry.

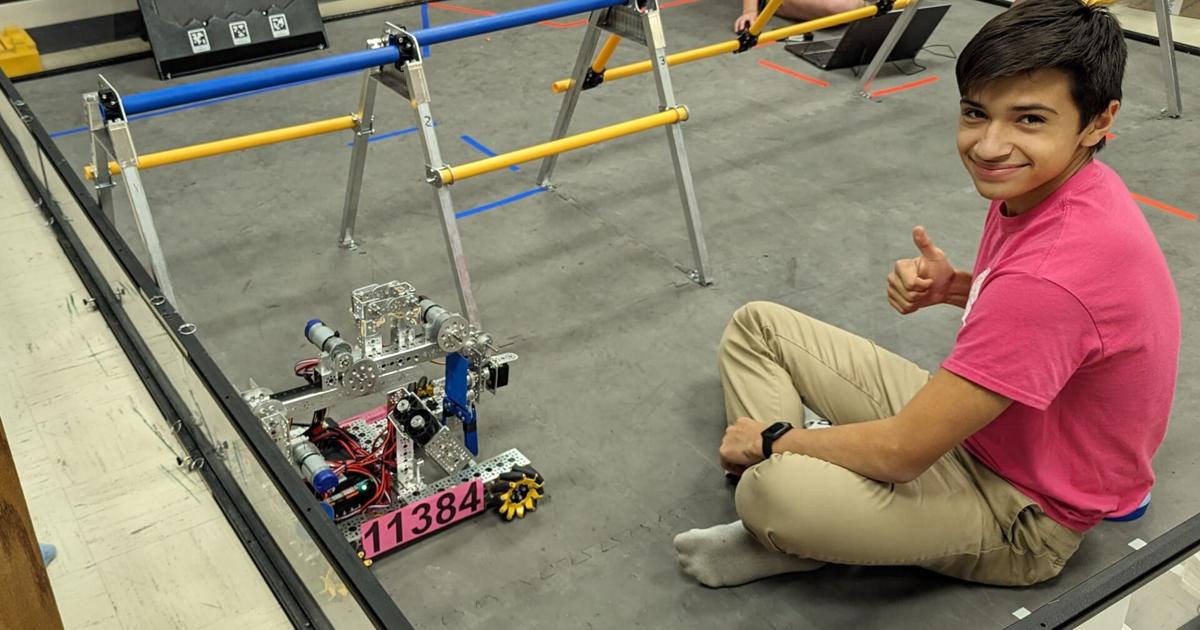

- Collaborative Framework for Robotics Training — This project has Aris Technology as its principal investigator and is seeking to assist store owners by creating human-friendly robots that can assist workers on shop floors.

Atiya Irvin-Mitchell is a 2022-2023 corps member for Report for America, an initiative of The Groundtruth Project that pairs young journalists with local newsrooms. This position is supported by the Heinz Endowments.

Advanced Robotics for Manufacturing Institute / Siemens

Subscribe

Knowledge is power!

Subscribe for free today and stay up to date with news and tips you need to grow your career and connect with our vibrant tech community.

Technically Media