We are often told that automation, AI, robotics, and other Industry 4.0 technologies will take over boring, repetitive, low-value tasks, freeing up skilled experts to do what they are best at. Yet there have been countless examples in recent months of technology doing the exact opposite: taking over creative roles and turning human workers into button-pushing support staff.

However, one area where the promise of automation is being fulfilled is in essential lab work in life sciences and healthcare. In these critical research centres, in areas such as genomics, cancer screening, and pharmaceuticals development, highly skilled, PhD-level staff spend hours manually using pipettes to insert samples into test tubes. Day in, day out.

This is vital, precision work – the bedrock of testing – yet also boring, repetitive, exhausting, and at high risk of error. As a result, staff churn is high at a time when research labs, which are themselves scarce, are under enormous pressure to innovate and increase their throughput.

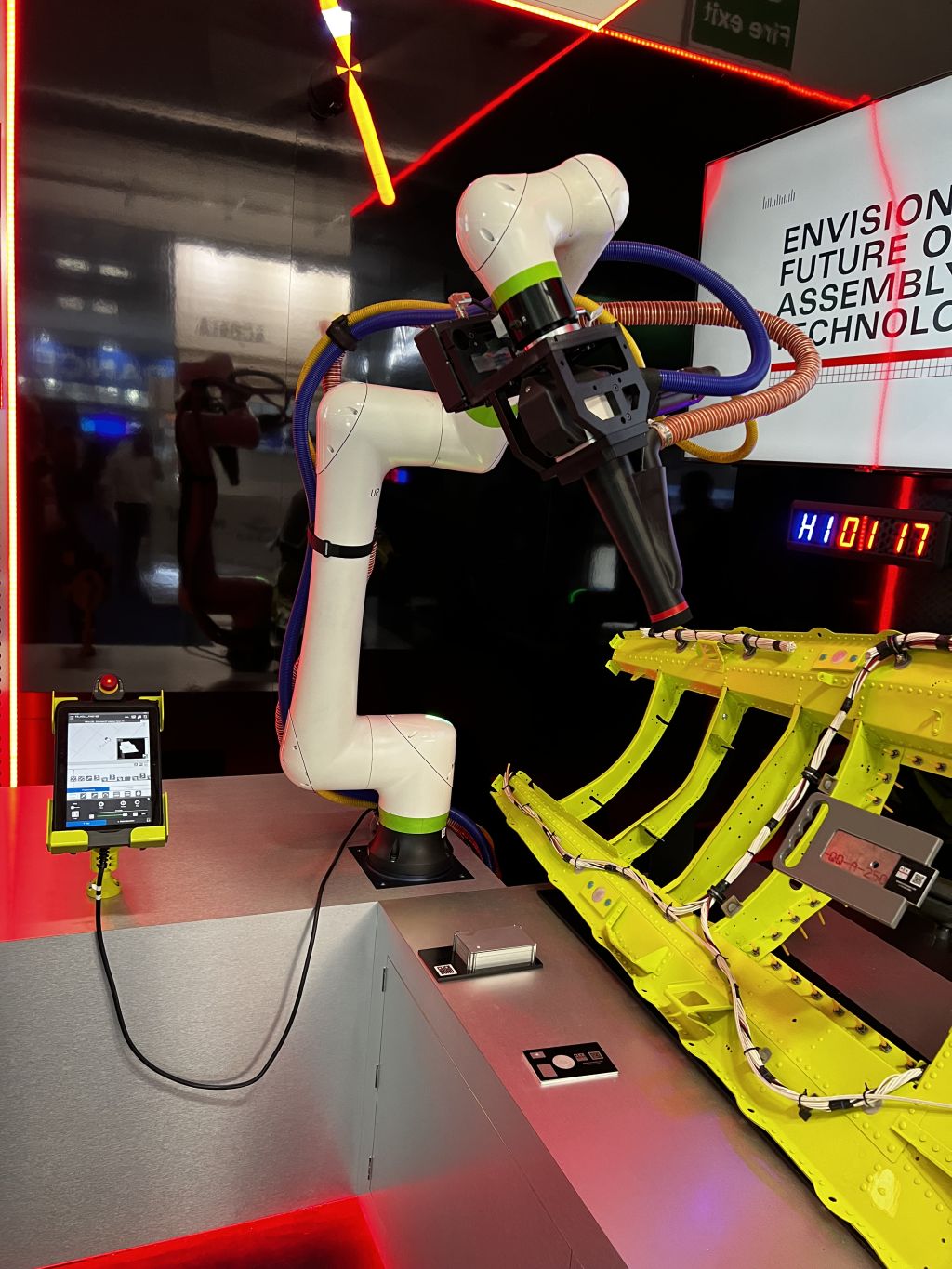

Open, integrated automation’ is the mantra of British lab automation specialist, Automata. Earlier this month, it announced a partnership with renowned cancer treatment centre The Royal Marsden NHS Foundation Trust to establish the UK’s first fully automated system for clinical genomic testing.

An announcement from both organizations said:

The new installation will increase the hospital’s next-generation sequencing (NGS) capacity by around 2,000 tests each month, and expand the range of tests the specialist cancer centre can perform. NGS technology allows scientists to analyze DNA and RNA gene sequences to deliver more personalized treatments on a large scale.

The newly automated service will also enable The Royal Marsden to launch a new genetic screening service to identify people at risk of cancer based on their inherited genetic mutations.

Automata’s LINQ platform features an expandable smart bench, integrated automation functions, and proprietary lab orchestration software. The new Royal Marsden facility will feature 20 such benches, six robots, and nearly 40 specialist instruments.

Due for launch in early 2024 – in January, Automata hopes – it will be based in the NIHR Centre for Molecular Pathology, which also welcomes researchers from The Institute of Cancer Research.

Professor Michael Hubank, Scientific Director of Clinical Genomics at The Royal Marsden NHS Foundation Trust, and Professor of Translational Genomics at the Institute of Cancer Research, explained:

Once opened, the facility will enable us to analyze the genetic make-up of more cancers than ever before, helping us to target cancer treatments and identity those at higher risk of the disease.

Genomic testing is currently labour intensive and involves repetitive tasks, so fully automating the process will give our scientists and technicians more time to focus on quality and on the scientific aspects of their important work.

Great news. And Automata has similar projects ongoing with, among others, the Francis Crick Institute, synthetic biology/stem cell specialist Bit Bio (a Cambridge University spinout), and the NHS University Hospital of Southampton, which focused on COVID-19 testing during the pandemic and is now expanding into new areas.

Do you want to drive change or not?

However, Automata’s roots are in more general robotics, based on the EVA cobot – a customizable, multi-purpose robotic arm designed for a variety of different applications, including in manufacturing. So, how and why did the company embark on its journey to become a completely different, more specialised business? And what does that tell us about the market for robotics and automation?

Nick Pattinson is Automata’s VP of Product Strategy. He tells me:

In the past [as a general robotics company] we talked a lot about democratizing robotics and democratizing automation in industry. And that mission statement, in many ways, is still the same. Automation is hopelessly underused in so many sectors, especially in use cases where high flexibility and simplicity in solving automation problems is needed.

But when we took EVA to market and saw more and more applications for it, everything from throughput, manufacturing, and product-testing to life sciences, we started seeing more and more opportunities within the lab automation space.

We recognized that solving business-level problems was the way to drive mass adoption of automation. But if we were going to start taking that on, then we had to do it within a specific market. And that was life sciences.

We rapidly saw that, to build a robot for that space, it wouldn’t need all the axes that EVA offered. And we have always had the viewpoint of ‘only innovate where you need to innovate’. In other words, focus on the outcome you’re trying to drive.

So, EVA – which was the foundation product of the company – was discontinued, despite being a well-designed device and, apparently, the right idea at the right time. What does that tell us about the market for general robotics? Is it too broad, and in need of too much local customization to succeed? Should automation companies focus on niches and verticals instead?

Pattinson says:

A lot of companies in general robotics are doing incredibly well and innovative amazingly. But I do think that the mass adoption of automation does not live in that stack. And because of that, there is only so much change you can drive if you limit yourself to solving very broad, general problems. So, the decision we faced was, do we want to drive change? Or do we just want to be a component provider?

Plus, we knew that the way any product, any technology, percolates through a market is by successful instances of it driving value.

In short, life sciences offered the opportunity to effect real change: not just in robotics and automation, but also in society. Improving and speeding up the screening of diseases like cancer, ultimately, saves lives.

And that’s not all. While many general robotics companies have to solve colossal engineering and programming problems, such obstacles are limited in life sciences. But why is that?

Focusing on specific problems

Our recent profiles of Canadian humanoid robotics provider Sanctuary AI explored how difficult it is to teach robots to perform simple, manual tasks that human beings can do without thinking.

For example, it is hard to train a robot to recognize a cup or a hammer, pick it up, and place it on a shelf or in a drawer. This is because there are countless different types of cups and hammers – of different sizes, weights, and designs – and countless different shelves to put them on, in environments that may be similar, but may also be completely different.

To a robot that has no concept of what any of these things are, primitive tasks like these are almost impossible. This is why it is far easier to teach an AI about relativity, astrophysics, or quantum mechanics – things that most humans find baffling – because reams of data are available about all those topics, and more. Centuries of human brilliance lie behind that information, of course, but to a computer it is just machine-readable text.

But in life sciences, lab hardware tends to be standardized: a test tube, bench, pipette, and other specialist equipment will, broadly, be the same in every lab. This means that repetitive processes can be automated and replicated, opening up a global market – and to solve global problems.

Pattinson says:

Anyone could buy a robot and learn to programme it in very general terms quickly. But to solve specific business problems we need it to do a number of other things. We need it to ‘talk’ to other machines around it reliably. We need it to pick things up and put them down equally reliably, and have some intelligence in the way it does that.

In some markets, like manufacturing, that’s a really hard problem to solve, because the component itself is changing. And the handling of variable items and unusual shapes is not reliable enough for it to be mass adopted.

That’s why it is better to focus on specific problems. One of the big advantages that the life sciences has over manufacturing, for example, is they have implemented the SPS standard or footprint. This means that the vast majority of hardware has a standard shape and size, which is why integrated automation is able to boom in this market, even in small organizations.

You can start standardizing your approach without having to develop complex machine learning and computer vision solutions. That helps the democratization of this technology – that’s what standards do! So, it’s getting simpler for technology stacks to build on each other.

But general robotics companies? That will be an incredible place to get to if they can solve their own sets of problems.

So, how did the relationship with the Royal Marsden and others begin? Did conversations there help push Automata towards life sciences? Or had they already developed that expertise – a transformation that apparently began during the early years of the pandemic?

He says:

We had an introduction made. Because people who knew both our organizations, knew they were really struggling with this problem, and so it would be an incredible way to make a change.

The problem they and other labs have is so acute. We can make things so much better in the UK, and for the NHS, if we can use automation to scale up the amount of sequencing and genomic tests those labs can provide.

There’s a huge need right across the country, because labs tell us they don’t have the footprint or ability to hire enough skilled staff. Plus, it really blew our minds how hard it is to find lab space at the moment, how precious every square metre is. But at the same time, they are being asked to increase their output massively.

Finding lab staff – incredibly skilled, trained people – to come in and spend their days pipetting samples manually, all day and every day: that’s tough. They’re hard to find and even harder to retain in a job like that. But, at the end of the day, you really need their quality data and their expertise. All of this creates a burning platform in the industry.

Automation in this space could really spur mass adoption.

Neal Parker, Strategic Account Manager with Automata, adds another perspective: the growing commercial and healthcare imperatives:

The rising number and types of tests these teams are doing is the next big thing in pathology, and in diagnostic testing. And they continue to be asked by Genomics England to do more: more tests, and a wider variety of tests. Those demands are constantly increasing.

Ultimately, this is a good thing because we’re getting really impactful patient data that allows targeted cancer treatment, and the identification of individuals at higher risk of cancer. And, in turn, that allows the lab to do more with what they already have. Because this level of testing is only going to increase even more over the next few years.

But if you have someone with a PhD, who spent years training in their field, or a really experienced biomedical scientist, but they spend their days preparing and moving samples from one plate to another… this is exactly the pain point that we hope to solve.

Pattinson adds:

It’s worth adding that this is just one application area, the market for genomics testing. Outside of that, we have a number of large, similar deployments happening in different sectors. For example, with contract research organisations, and with advanced UK and European biotechs. And with a number of big pharma companies – the household names. So, it’s been a busy couple of years!

My take

Hats off to a company that was succeeding in one space having the confidence to completely change the business and solve a more serious – and focused – problem. A rare example of automation doing exactly what tech companies have long promised: freeing up skilled, talented, highly trained humans to do the stuff they really want to do – and that we all need.