Promise Robotics this week announced $15M funding in its Series A round.

Update: 10/31: A previous version of this story’s headline described Promise Robotics as a “homebuilding” startup. They aren’t actually constructing homes.

Pay attention to the news to even a casual degree and you’ll learn about how expensive the Bay Area is regionally, especially when it comes to housing. San Francisco, being a major city and tech hub, has an outsized presence for being the most expensive place to live. A lot of the media coverage around here focuses the housing crisis as being worse for marginalized groups, mainly in Black and Brown communities. This is true, but the economic demands also disproportionately affect the disability community. Considering the strict rules placed upon us to be eligible for governmental social services like Social Security, the idea that a disabled person could save money and someday become a homeowner is the definition of a pipe dream. Most disabled people are relegated to live in poverty due to said rules, so housing will forever be exorbitantly expensive. Even an inherited property can be unrealistic to maintain and stay atop of upkeep because of costs like renovations and property taxes.

Promise Robotics wants to make housing accessible to everyone.

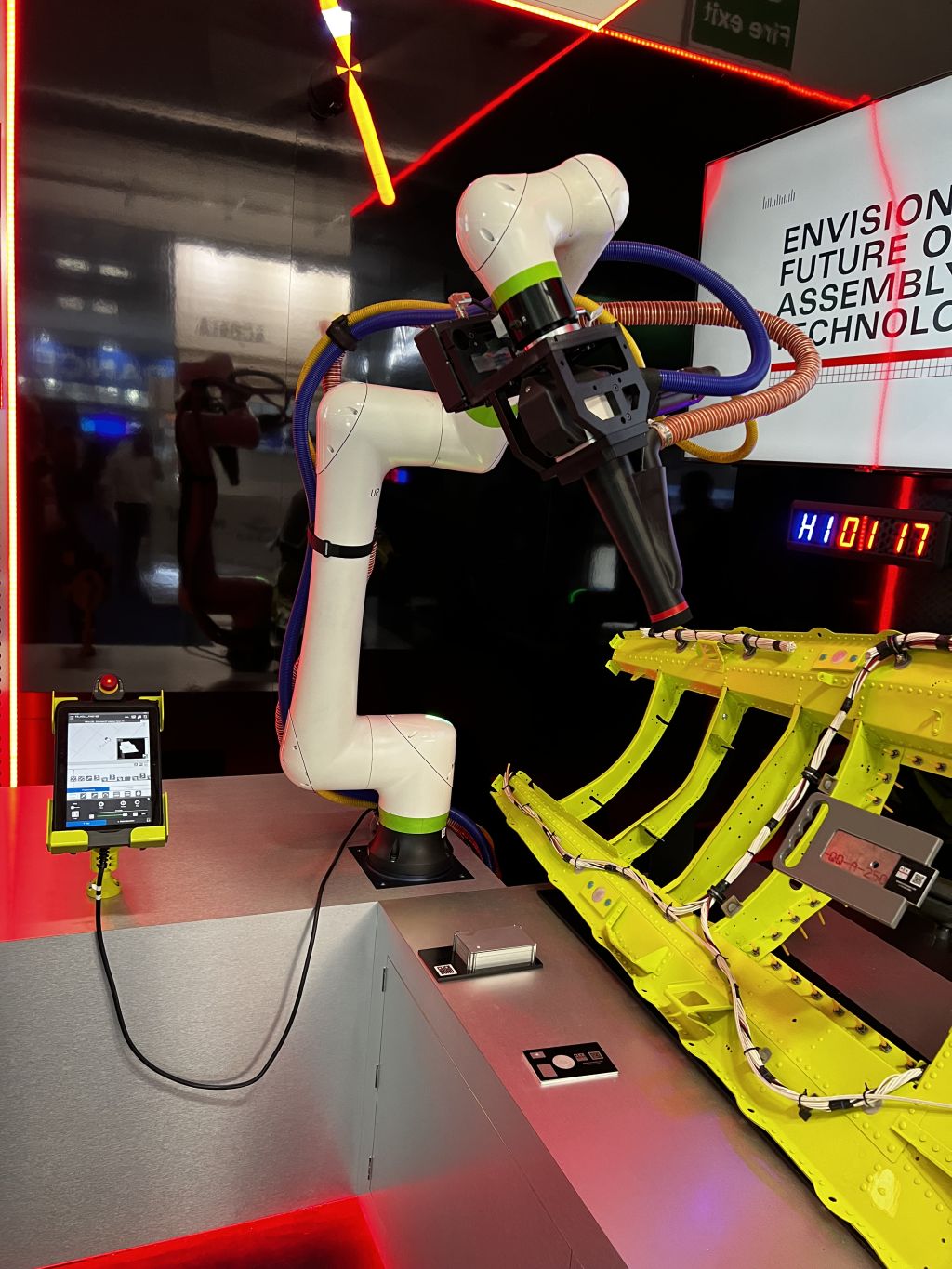

The Toronto-based startup, which on Tuesday announced a $15 million Series A funding round, uses artificial intelligence to, according to its website, “enable the building industry to harness automation toward producing more affordable and sustainable housing.” Furthermore, the company describes its work as “bringing the most intelligent, flexible, and compact industrial robotic systems to construction [using] our ready-to-deploy industrial production systems [which] are powered by a proprietary cloud-based software platform that manages the entire production lifecycle, from production planning to factory floor operations, scheduling, and logistics.” In a nutshell, Promise Robotics is using technology to build more affordable housing for everyone.

In an interview last week conducted over email, Promise Robotics co-founder and CEO Ramtin Attar explained the company helps the homebuilding industry address labor shortages, lower costs, and speed up construction by deploying automation at scale to the building of homes. This ranges from single-family dwellings to multi-story units.

Promise Robotics’ platform, Attar said to me, “turns off-the-shelf industrial robots into ready-to-deploy production systems powered by proprietary cloud-based software that manages the entire production lifecycle from automated robotic instructions to managing factory floor operations, logistics, and services.”

According to Attar, Promise Robotics’ technology stack is two-pronged. First and foremost is the company’s “core” system, powered by artificial intelligence that he told me “analyzes a building design, generates machine instructions and communicates the instruction via cloud to robots that work collaboratively and autonomously to produce components of the building,” adding that the system is “continuously learning about new tasks and improves overtime using sensing and perception.” This approach is unlike that of the automotive industry, where Attar said robots are repeating the same task over and over. By contrast, he said Promise Robotics’ robots are multitasking machines capable of building a different component every time. “At the core [of our work], we are developing the largest robotic library of construction tasks for all kinds of materials and assemblies for building,” Attar said.

The second pillar, as Attar described it, is what he called Promise Robotics’ “intelligent management platform.” The platform, he told me, is proprietary in nature and “manages the entire production lifecycle from automated robotic instructions to managing factory floor operations, logistics, and services.” It’s a system that’s foolproof insofar as Attar said human workers need not “[know] anything about robotics and automation” in order to manage the entire production pipeline.

In simpler terms, Attar likened his system to Legos, telling me software-powered robots build elements like walls and floors which are then flat-packed and shipped to locations where they are unboxed and rapidly assembled. “But in the real world, not all Lego blocks are the same dimension or require the same materials, so this can be incredibly complex,” he said. “Our software automates this process for construction companies, making it quicker, easier, and cheaper to produce homes.”

Related to what I wrote at the outset, part of the problem with more accessible housing is the fact Rome wasn’t built in a day. It takes time, money, and manpower, to build housing units; this means people in need of a roof over their head necessarily have to wait for construction to run its course. This is exactly the problem Attar and co-founder Reza Nasseri set out to solve with Promise Robotics. In order to close the housing gap, Attar said, “we must target where the pain points start—the cost and time it takes to build homes themselves.” Beyond bureaucratic stuff like permitting, the main culprit, for, say, an apartment building taking eons to appear is due to what he called “clunky workflows that drive up costs. Our automated systems can be deployed rapidly for low volume or high-volume production across many regions particularly where there is labor shortage.” Currently, Promise Robotics is working on addressing housing needs in the Northwest Territories for indigenous communities, with Attar saying the company also is “building a pipeline of demand by homebuilders” in the United States and Canada.

“With our automated system, homebuilders can assemble and lockup a single-family home in about six hours and a 64-unit, three-story apartment building in two weeks. This is about 70% faster than traditional methods. Not to mention there is virtually no waste or faulty craftsmanship,” Attar said. “We estimate that with this time saved, we can help the industry save $130 billion just in capital savings per every million homes. That’s a lot of properties that can be built quickly.”

With regards to feedback, Attar said he finds it “incredibly powerful” every time he watches someone press a button that summons two robots in building a twenty-foot wall in a short time with precision, all done autonomously from a stack of lumber. Customers will ask Attar how the robots know how to do their jobs, especially when it comes to walls with different features and heights, as well as how the robots don’t clash with one another. “This is when customers have their ‘aha’ moment and grasp the power of AI,” he said.

When asked about the company’s future, Attar said in the next few months Promise Robotics will be setting up its first robotic production line at a micro factory in Alberta, Canada in an effort to “kickstart” partnerships with homebuilders. In the longer view, the company has its sights set on “[making] our turnkey factory production solution available to the broader North American homebuilders” by 2025.

“Our mission is to harness automation to create a more affordable and sustainable built environment,” Attar said of what Promise Robotics’ strives to achieve. “In times of a housing crisis and climate change, this requires multiple players to work together, and we’re excited for what our industry can accomplish as technology modernizes.”