Mark Messina is the CEO of Addverb USA, a company that solves complex fulfillment challenges through robotics and automation solutions.

In today’s market, warehousing faces three primary challenges. Soaring real estate prices make storage efficiency paramount; no warehouse owner wants to foot the bill for storing mere air.

Labor intricacies pose the second challenge. Attracting and retaining warehousing staff is difficult, and the costs associated with onboarding and training are significant. Additionally, concerns about labor safety further complicate the industry landscape.

Storing perishables is the third challenge, demanding stringent conditions and specialized solutions.

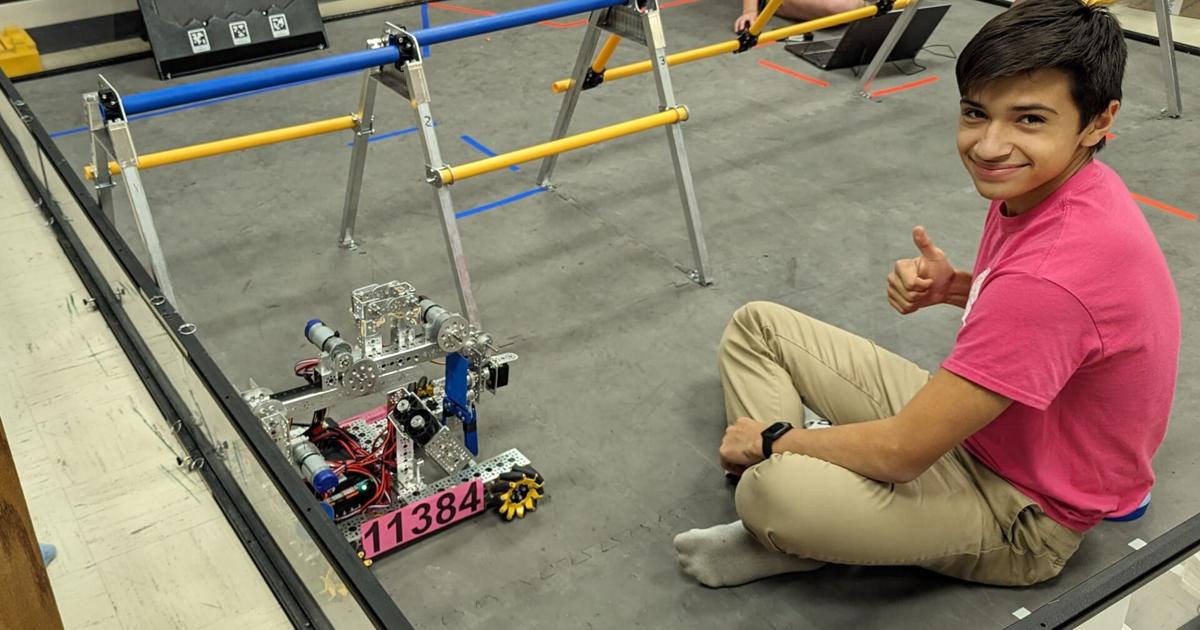

However, there’s a silver lining: robotics. These advanced systems are transforming warehouse operations by enhancing storage efficiency, streamlining labor processes and ensuring heightened safety for staff. Moreover, they ensure optimal conditions for perishables, reducing wastage.

Major industry players are doubling down on the use of robotics, as evident from Amazon’s incorporation of more than 200,000 mobile robots within its expansive warehouse network. But why are leading brands betting big on robots?

Let’s explore why and delve into the pivotal role of robotics in warehousing, exploring the challenges, risks and emerging trends set to reshape the industry’s future.

Pivotal Role Of Robotics In Warehousing

As a testament to its growing importance, the warehouse robotics market is projected to reach $14.52 billion by 2029.

Optimum Warehouse Space Utilization

In the quest for optimal warehouse storage utilization, several challenges emerge. One notable obstacle is accessing vertical storage without the assistance of robotics. Additionally, the e-commerce sector, with its vast diversity of SKUs, further complicates matters. Inventory can range from petite jewelry items to sizable home appliances.

Traditional challenges persist as well. Legacy design choices, fixed aisle widths tailored for conventional forklifts and predetermined rack sizes often don’t mesh with the varied dimensions of products.

Dense racking systems, which condense aisles and deepen storage slots, and rainbow pallets, where an assortment of SKUs coexist on a single pallet, can increase fulfillment speed when coupled with intelligent automation systems.

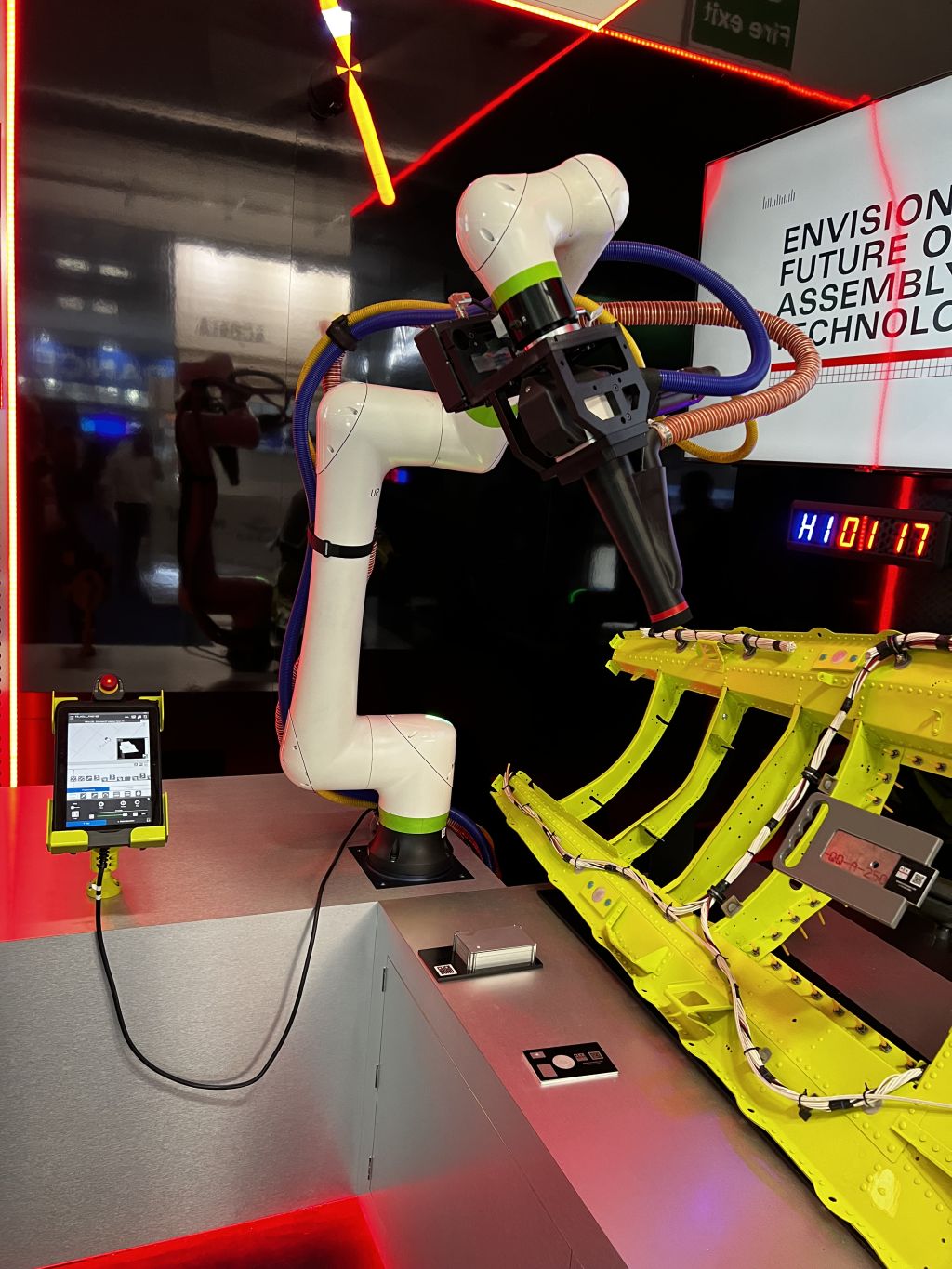

Robotics-driven picking systems master the art of seamlessly maneuvering and extracting items from sky-high racks. These advanced systems glide along built-in tracks within the shelving architecture, making pallet storage and retrieval a breeze.

Legacy-designed warehouses demand a radical overhaul, leveraging the insights offered by data analytics. Additionally, embracing mobile shelving units that move along tracks eliminates the need for fixed aisles, further optimizing floor space.

By smartly maximizing space, warehouse operators can counteract the rising costs of real estate. Plus, faster fulfillment means delighted customers every time.

Increased Safety

Pickers might traverse 12 to 15 miles daily, often carrying items or repetitively picking and placing them. In many warehouses, rudimentary mechanization and tasks like lifting or interacting with conveyor belts can lead to ergonomic injuries, underscoring a primary safety concern in the industry.

Reduction of Physical Strain: Advanced robots can handle repetitive tasks, eliminating physical fatigue for humans.

Navigation and Collision Avoidance: Robots with advanced navigation algorithms ensure safe and efficient movement within warehouses.

Ergonomic Task Allocation: AI can assign riskier or strenuous tasks to robots, ensuring humans work within ergonomic limits.

Safety Monitoring: AI-driven surveillance ensures safety protocols are maintained, alerting supervisors of any breaches.

Predictive Maintenance: AI predicts machinery malfunctions, reducing injury risks from equipment failures.

Reduced Wastage And Damage

Managing perishable items like fresh produce and beverages is a delicate balance, often marred by wastage and damage due to temperature mishaps and mishandling. This not only hits the bottom line but also exacerbates food waste and environmental issues.

The good news is that advanced robotics can offer precise temperature and humidity control, ensuring goods stay fresh. Additionally, equipped with sensitive grippers, these robots handle items with the perfect touch, drastically cutting down on damage.

Potential Risks And Challenges

While robots enhance warehouse efficiency and safety, owners should understand the implications of adopting intelligent automation.

Job Displacement: Robotics, like Amazon’s Kiva robots, have automated tasks previously done by humans, reducing the need for human involvement in repetitive tasks. Amazon offers reskilling programs for workers impacted by automation, helping them transition to more technical or automation-resistant roles.

High Costs: Despite the substantial upfront costs, training and maintenance associated with intelligent automation systems, companies, including DHL, with its robust $15 million commitment, remain undeterred in their pursuit of automation. Their willingness to invest stems from the profound long-term advantages automation promises.

Security Concerns: Increased automation heightens vulnerability to cyberattacks and system malfunctions. Addressing these risks requires robust cybersecurity measures and a proactive approach to challenges.

Final Thoughts and Industry Trends

Warehouses are in the early stages of automation, with 15% mechanized and only 5% using advanced tools.

Current solutions, while beneficial, often lack seamless integration, resulting in efficiency issues. This drives innovators, like Boston Dynamics with its “Stretch” system, to develop more cohesive robotics that integrate mobility, vision and gripping autonomously unloading boxes. The industry is now entering a fresh phase of innovation.

Application-Specific Components: As robotics evolve, there’s a clear trend towards components customized for specific robotic tasks like object recognition and navigation. NVIDIA’s Isaac further highlights this trend with their specialized robotic sensors and chips.

Humanoids and Animal-like Robots: Emerging from single-purpose designs, robots are evolving towards versatile, multi-functional capacities. Humanoid and animal-inspired forms, reflecting natural adaptability, are at the forefront of this shift. Although still nascent, within a decade, these robots are poised to pervade industries, offering 24/7 efficiency without recurring costs, signaling a transformative industry trend.

Collaborative Robots: ‘Cobots’ designed to work harmoniously alongside humans bridge the gap between full automation and human-centric tasks, combining the best of both worlds for safer and more efficient work environments.

Robotics-as-a-Service: Companies are gravitating towards RAS models, allowing for flexible financing and tying costs to actual operational needs.

As we stand on the brink of this transformative era, the question is not whether to adopt but how swiftly you can lead the change.

Forbes Technology Council is an invitation-only community for world-class CIOs, CTOs and technology executives. Do I qualify?