Amazon is turning its robotics ambitions up a few notches with two new tests that could speed up delivery and revise labor conditions across the e-commerce giant’s fulfillment network.

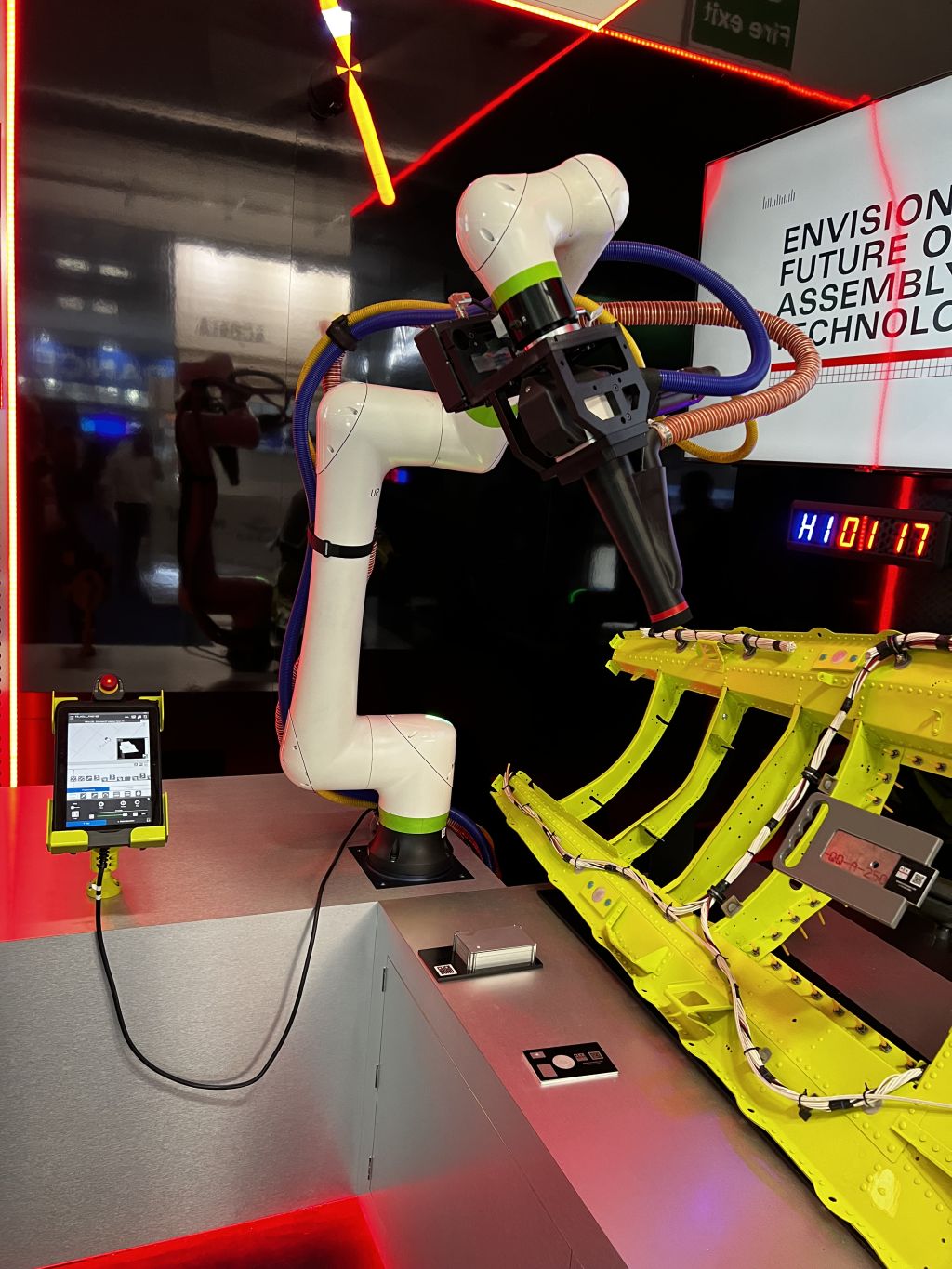

At a Houston fulfillment center, Amazon is trialing Sequoia, a warehouse-ready robotic system that speeds up the process of packing and moving items. And near its hometown of Seattle, the tech titan is testing Digit, a bipedal mobile robot that can navigate a warehouse while also grasping and deftly handling a variety of items.

More from Sourcing Journal

Amazon said Sequoia helps the company identify and store inventory received at its fulfillment centers up to 75 percent faster than its current pace. This means the company can list items for sale online faster.

Sequoia order processing time at a fulfillment center by up to 25 percent, Amazon said. This can help improve shipping predictability and increase the number of items offered for same-day or next-day delivery.

Technology like Sequioa could help Amazon spend less money on payroll, according to one expert.

“Amazon will do what they can to reduce their labor costs which means where possible, they’ll add robots that meet their needs,” said Brittain Ladd, a supply chain and logistics consultant and strategy advisor at Shatranj Capital Partners.

Sequoia integrates multiple robot systems to containerize inventory into totes. The system works by having mobile robots transport the inventory directly to a gantry, a tall frame with a platform supporting equipment that can either restock totes or send them to an employee to pick out inventory that customers have ordered.

The technology appears to be targeting one of the major concerns surrounding Amazon—workplace safety.

The totes are delivered to individual workstations within each employee’s “power zone,” the area between the mid-thigh and mid-chest, according to Amazon parlance. The system is designed so employees will no longer have to regularly reach above their heads or squat down to pick customer orders.

Amazon has long taken heat over its warehouse injury rate, especially when it comes to musculoskeletal injuries caused by repetitive motions like reaching, squatting, pushing and pulling. But the tech titan has long maintained that the statistics used against it aren’t put into context.

According to a blog post from Scott Dresser, vice president of Amazon Robotics, recordable incident rates and lost-time incident rates were 15 percent and 18 percent lower, respectively, in 2022 at sites deploying Amazon robotics solutions versus non-robotics sites.

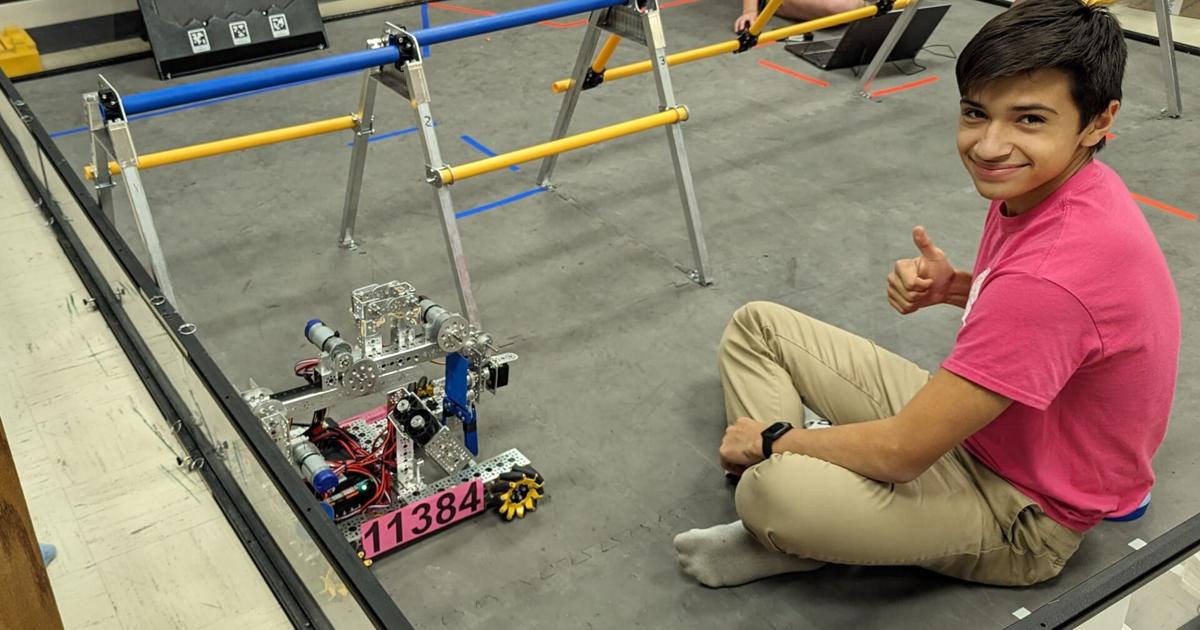

The other big robotics test, Digit, was developed by Agility Robotics, which got a $150 million investment from Amazon in last year. The bipedal robot can walk forward, backward, turn around and bend, and can grab, lift and move totes around a warehouse.

Dresser emphasized that the robot is designed to “work collaboratively with employees,” saying that the first use of the tech is to help with tote recycling—the repetitive process of picking up and moving emptied totes.

“Digit can move, grasp and handle items in spaces and corners of warehouses in novel ways,” Dresser said. “Its size and shape are well suited for buildings that are designed for humans.”

Amazon said it now has 750,000 robots working collaboratively with employees. These high-tech devices take on highly repetitive tasks and free staff up to take on other responsibilities.

“Amazon’s goal is to introduce robots and when necessary, hire more labor,” Ladd told Sourcing Journal. “Over a period of time, Amazon will automate the worst aspects of their fulfillment centers leaving only the need to hire more skilled workers. By 2030, if everything goes according to plan, Amazon could automate 30 percent to 50 percent of the positions that are currently manual.”

However, the juggernaut “won’t purchase a lot of Digit robots unless they meet Amazon’s expectations,” Ladd added.

The robotics deployments were part of an announcement that also touched on reducing packaging waste in Amazon warehouses and new drone delivery capabilities.

The company’s automated fulfillment center in Euclid, Ohio is the first in the U.S. to replace plastic delivery packaging with curbside recyclable paper packaging solutions. This is part of a multiyear effort to convert its U.S. fulfillment centers to paper, Amazon said.

Amazon’s packaging engineers redesigned machines that were previously packaging items in non-padded plastic bags. The machines now use a built-in sensor to identify the correct size for non-padded paper packaging of products, including clothes, kitchen supplies and sports equipment. A heat-sealing technology is then used to ensure items are securely closed.

The e-commerce giant also developed a new machine that creates on-demand, curbside recyclable, made-to-fit packages for products that require more protection than a non-padded bag. This machine measures an order’s dimensions and then creates a right-sized, protective package using a type of corrugate that is flexible and lighter than the typical box.

Amazon also announced it will expand its drone delivery project to customers in Italy, the U.K. and a third, undisclosed U.S. location in late 2024. In addition to the new delivery sites, Prime Air showed off the MK30 drone design, which can fly twice as far as previous models and is quieter, smaller and lighter.