Co-founder, Cardinal Robotics—providing products and services that drive robot adoption.

The robotics industry has seen high failure rates despite rapid growth and innovation. Based on my experiences and recent analyses, there are several key reasons behind the high failure rate of robotics startups, which can be grouped into a number of themes.

While many founders excel at technological innovation, they often struggle with critical business aspects. Lacking strategic planning and execution across areas like operations, marketing, partnerships and product-market fit can undermine even the most brilliant robotic designs.

Specifically, robotics ventures frequently fail due to insufficient business acumen among technical founders, misjudging timing and value in an evolving market, subpar user experience that hinders adoption, misalignment with investors on goals and timelines, and attempting to solve diffuse or hypothetical problems rather than clearly defined customer needs.

Challenges In The Robotics Industry

To compound these issues, robotics companies also face at least a few challenges that are industry- and hardware-specific.

• High cost of engineering and talent, leading to shorter capital runways.

• Expensive components, materials and manufacturing, leading to expensive product iterations.

• Lack of mature business models and pricing models.

• Lack of common reference development platforms for new entrants to leverage, creating inordinate expense to “reinvent the wheel.”

• Long sales cycles with expensive customer acquisition.

• Costly support and maintenance after hardware delivery.

• Immature distribution and partner channels to launch with.

• High cost of ownership, making scaled deployments challenging to achieve.

• Pressure from investors and stakeholders to achieve unrealistic growth objectives and development milestones.

• Fear and resistance of change to workflow integration requirements from clients during adoption.

For example, many founders underestimate the difficulties of building a company, overspend early or have mismatched goals with investors. Robotics solutions often arrive at the market too early or too late, get over-engineered or are priced higher than the problem’s value to users. Usability issues like poor interfaces, difficult workflow integration or unreliable performance severely limit adoption.

Tips For Success

I’ve seen many experts advocate that robotics companies need a number of strategic partnerships to actually succeed—both customers and an ecosystem of system integrators, financiers and so on.

During the product development cycle, strategic partnerships with potential customers can help you test concepts in real-world environments early. This provides invaluable feedback to improve both technical and business aspects before launch. Partnerships with systems integrators also help overcome integration and implementation hurdles, while partnerships with financiers and banks can help build innovative pricing models, such as opex versus capex pricing.

Other key success factors include focusing on solving a clear customer problem extremely well rather than over-engineering complex general-purpose robots. Software and user experience design also require as much attention as hardware development. Business model innovation is equally important as technical innovation.

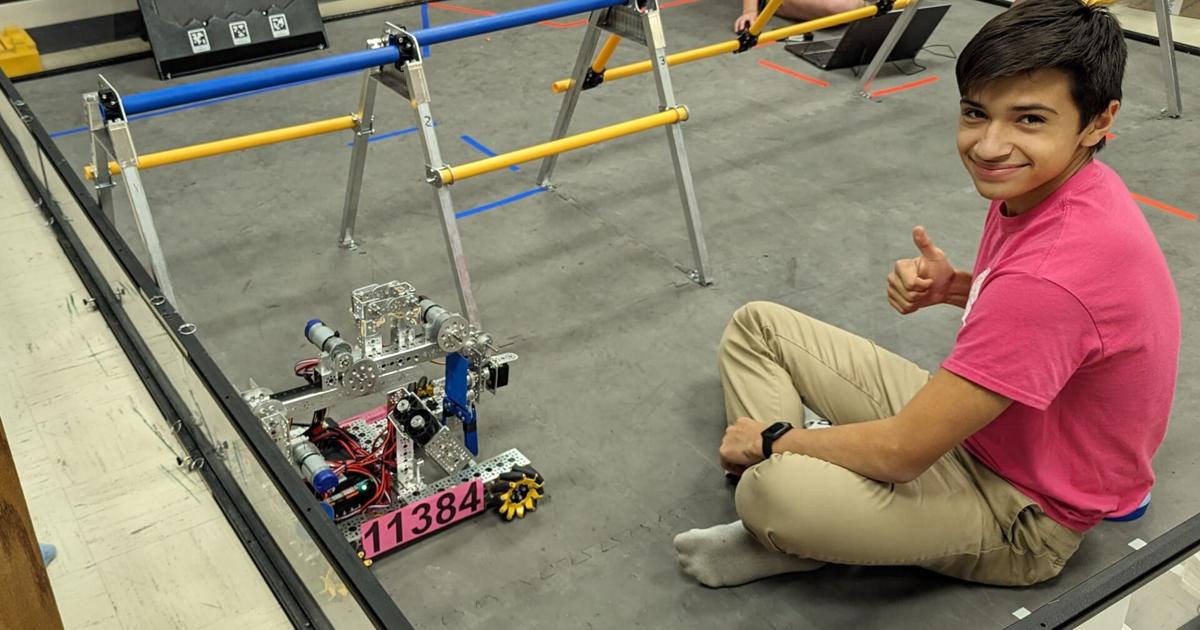

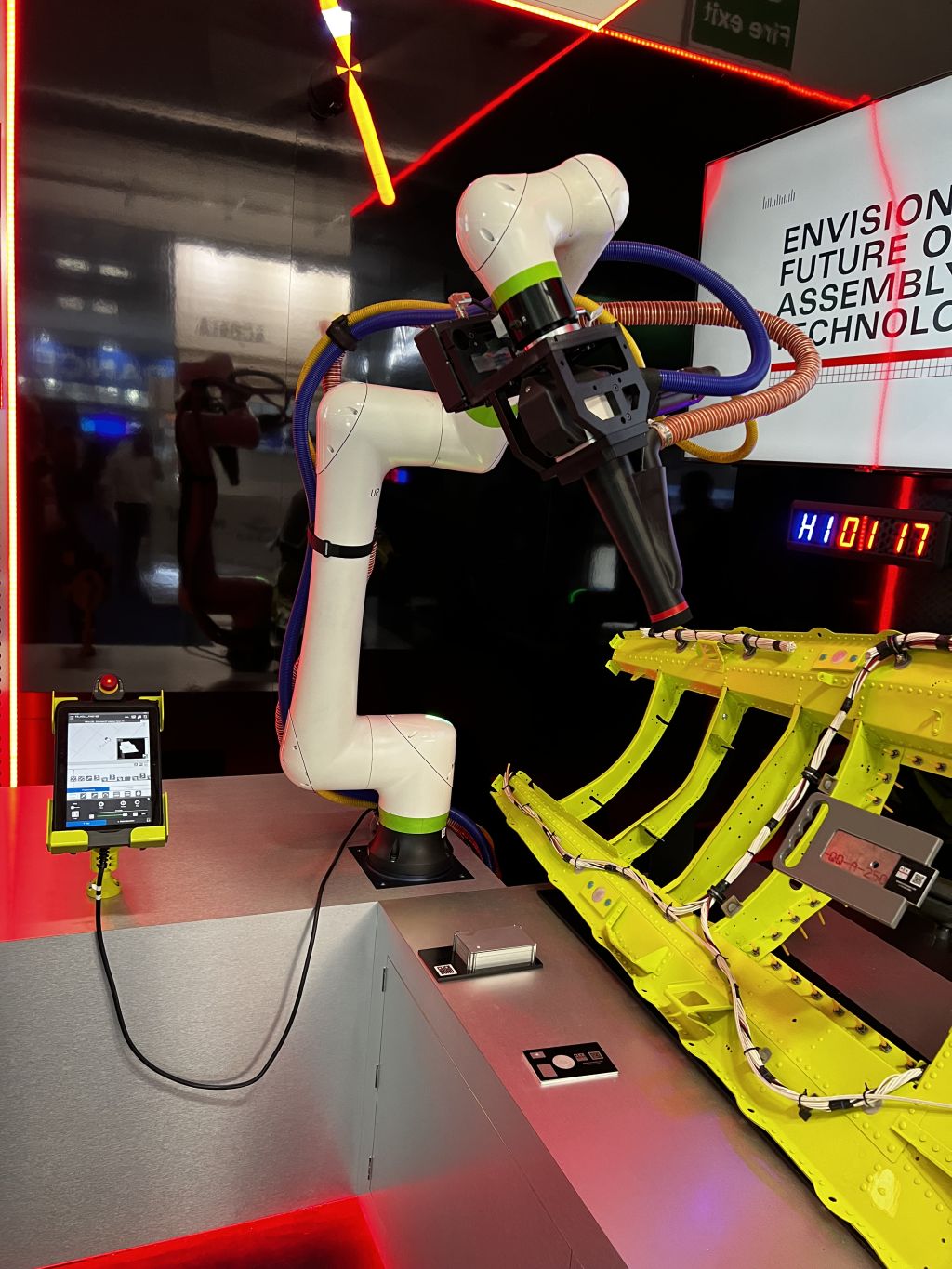

One domain of robotics called “cobotics” (collaborative robotics) aims to have humans in the loop with robots, with the objective that the robot will help improve human productivity rather than replace them.

For instance, cobots aim to address labor shortages and cost pressures across many industries like manufacturing, warehousing and hospitality. By safely automating repetitive tasks, cobots maximize constrained human workforces plagued by high turnover and retirement. Cobot examples include a diverse set based on application: autonomous cleaning robots, restaurant delivery robots, smoothie/beverage/coffee making robots, smart factory cobots and robot arms that are designed to work with humans.

Though cheaper than industrial robots, they require large upfront investments many smaller businesses cannot afford; hence, partnerships are appealing as a go-to-market strategy for robotics companies. Partnerships to smooth integration and adoption will be critical for cobots to live up to their labor-saving potential.

Looking Ahead

The adoption of robotics is a real industry issue and requires a number of pieces to fall into place. With the current trends of aging populations across major markets, there is an increased need for automation and robotics adoption. The labor shortages will make robots more cost-effective over time.

However, technical innovation alone will not guarantee a robotics startup’s success. Business strategy, strategic partnerships, market fit, usability and solving a clear customer problem are equally critical for success.

Forbes Technology Council is an invitation-only community for world-class CIOs, CTOs and technology executives. Do I qualify?