Fostering the diversity of ideas emerging from countries with small populations like Australia can propel organic growth and progress innovation more rapidly than expected.

One example of an innovation that progressed rapidly from ideation to commercialisation is a mango auto-harvester with a five-second return-cycle time that was developed by Central Queensland University (CQU) and Freelance Robotics.

The idea germinated from the Croc Pitch’s ‘10 minutes for $1 million’ – a Shark Tank-like event that encourages commercialisation of innovative products and technologies. Croc Pitch, which is run annually through the Darwin Innovation Hub, is an entre to venture capital for start-ups through the Paspalis Innovation Investment Fund and has become a driver of job creation opportunities, particularly in northern Australia.

“The drivers for automation in the mango industry are clear. Overcoming labour shortages for mango farmers due to prohibitive climatic conditions is a major challenge,” Freelance Robotics’ general manager Dr Amanda White said on the latest episode of the Commercial Disco.

“CQU spent four years developing a fit-for-purpose system and approached the problem with deep engagement with the growers. Subsequently, we have a technology that is at the point of commercialisation (within the next 12 months).”

“The real purpose of being there (for local farmers) is advanced manufacturing. I’m looking to get a new type of supply chain off the ground for the Northern Territory.

“When we’re thinking about supply-chain resilience, diversity is a positive impact factor. So, this is an opportunity to upskill and transition for equity of technology into northern Australia.”

Australia needs to adjust societally to changes taking place due to robotics in automation. As outlined in the 2019 “Innovation Imperative” report by the OECD, more than 800,000 jobs are expected to disappear to automation in the coming five to 10 years. Upskilling and upscaling programs are expected to offset this by creating more than one million jobs.

However, Dr White’s experience as a registered psychologist with the Psychology Board of Australia made a startling discovery from her focus area of complex comorbid diagnoses: “I had a very clear indication that the people affected by this transition to robotics might not be well informed or highly engaged,” she said.

By automating many of the required workforce tasks without a developed approach would not lead to meaningful career paths, and could result in systemic unemployment.

Dr White made the decision, then and there, to transition from psychological practice into evidence-based practice for societal changes at an industrial level.

Change-management program RoboTradies was born soon after for the purpose of creating an adaptative workplace where upskilling is supported for the overarching business case. Importantly, the program alleviates or eliminates employee layoffs.

“RoboTradies is designed for when a new technology deployment takes place,” she said. “We address wastage from the start, because the human and machine operation is critical to be able to successfully move through, not just deployment, but overall success.”

When building technology systems that work, sector-specific deliverables are paramount. Having the right support to upskill the operators of this technology for different businesses and users requires “deep dives”.

“We speak better to investors and the business when we’re not doing everything for everyone, all the time,” Dr White said.

As a result, the two-year-old Industrial Robotics spun off Freelance Robotics with a specialty in advanced manufacturing.

“Just before COVID-19 broke, the World Economic Forum allocated Queensland as an advanced manufacturing hub, globally” she said. “That allocation was not made because we were doing something exceptional, but because we have an exceptional problem — approximately 50 per cent of manufacturing concerns are small businesses that have 20 or fewer employees.

“So, the ability for those businesses to invest in (advanced manufacturing) technology has been limited,” she said.

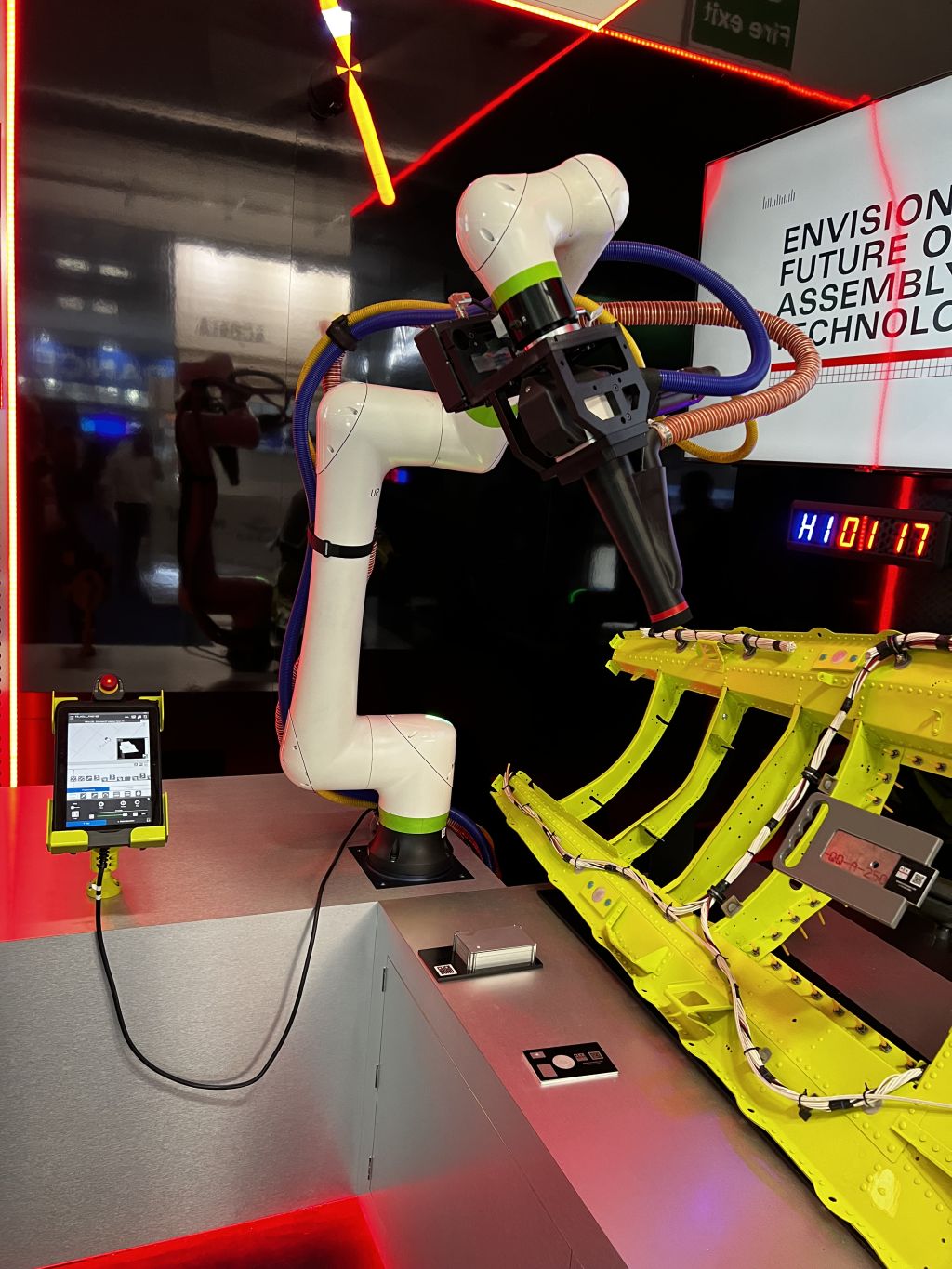

The development of a “world-first” technology called Blue Dragon FRAMEwork is one such solution. This is an industrial Internet of Things that allows for repeat manufacturing using a robotic arm — without the need for staff with high digital literacy.

This applies directly to agricultural technology, which is as unique as the Australian landscape. It must adapt to various challenges, such as crop types, field conditions and resilient renewable energy sources — and this requires analytical data solutions that help farmers make informed decisions.

With advancement comes vision — and the capability for smart systems and connectivity in remote farming areas is no longer a tech-equity idea, but the robotic realm of “dreamers and doers of a highly ranked and exciting nation”.

“Developers must consider how to make robots cost-efficient and applicable to a wide range of farm sizes across Australia,” Dr White said.

Do you know more? Contact James Riley via Email.